Machine Downtime Tracking. Made easy.

TrackMyMachines gives you the tools and data you need to reduce or even eliminate your machine downtime.

Measure Your Downtime

Install the TMM hardware on any machine, measure machine downtime.

Calculate Real Impact

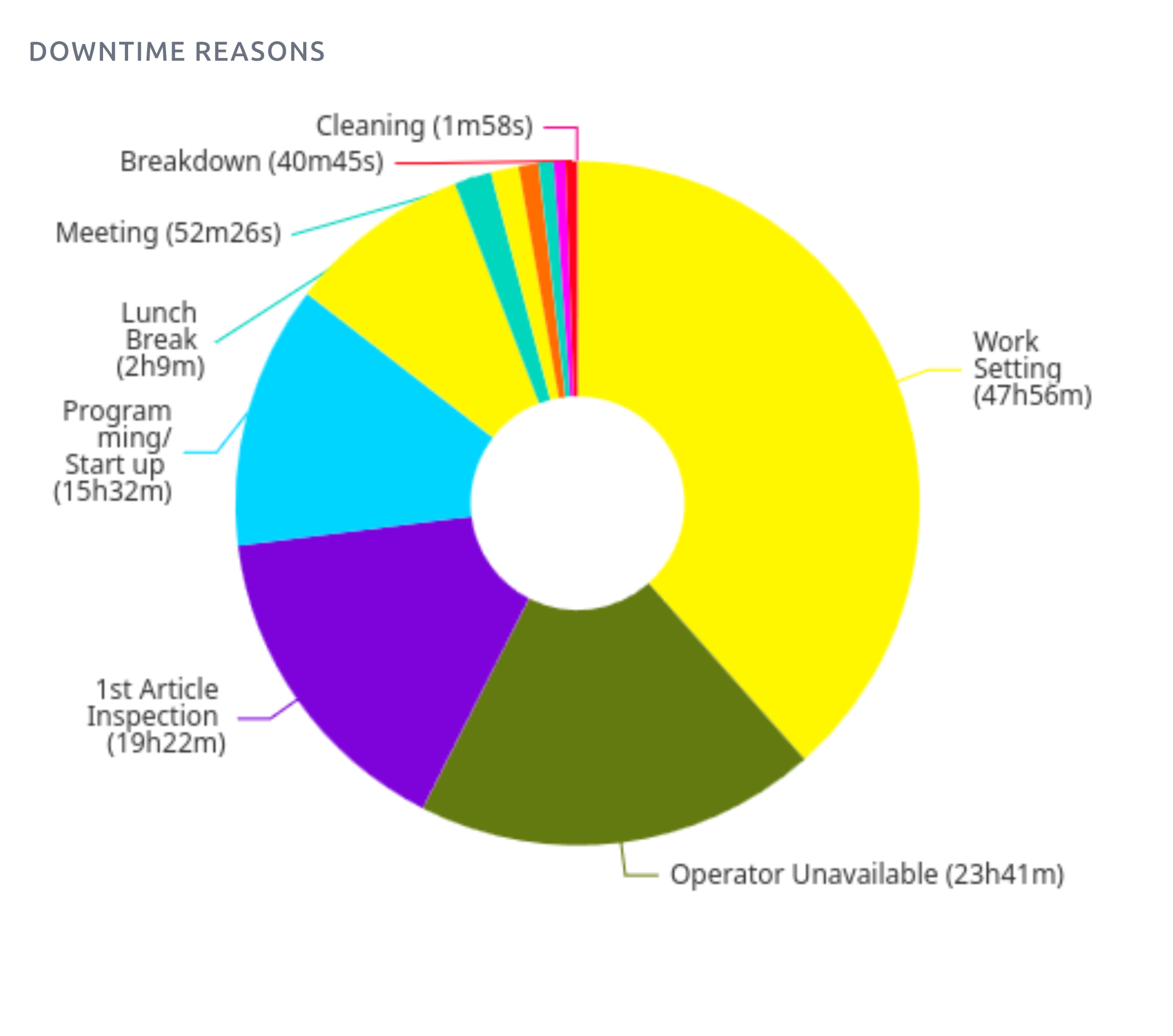

Visualise and report hours lost to different reasons per machine, shift, cell or factory.

Take Decisive Action

Make data-driven decisions and take action to reduce downtime.

The Hidden Cost of Machine Downtime

Some manufacturers lose up to 60% of their shift time to machine downtime.

Every minute your machines aren't running is costing you money. For a typical CNC machine, downtime can cost between £50-£200 per hour in lost production.

From planned to unplanned downtime, the sources of machine downtime in CNC machines include reasons like:

- Part loading

- Job changeovers

- Cutting tool changeovers

- Breakdown

- Tool setting

- Work setting

- Material handling

- Operator availability

With TrackMyMachines, rather than guessing where your machine downtime comes from, you can know. Then take action to mitigate it.

£5,000 of machine downtime saved with one operational change

Gardner Denver transformed their operations by tackling downtime head-on. Discover the exact steps they took to unlock thousands in savings and boost capacity.

Read The Case StudyYour 3-Step journey from downtime to uptime

Starting with TrackMyMachines is simple, and designed for immediate impact.

1. Connect

Install the TMM Connect device on any machine in 5 minutes. Minimal disruption to your production. Real-time data starts streaming to our secure cloud. Read our installation guide here

2. Monitor

Visualize your factory's true productivity. Operators log downtime reasons with a click, building an undeniable body of evidence for analysis.

3. Improve, Continuously

Armed with the data you need, make data-driven decisions. Optimize maintenance, streamline changeovers, and justify spending with hard data. Read more about improving capacity here