Key Benefits

Find out how much you're really making on a job

A lot of manufacturers don't know exactly how much each job is costing them in labour or machine time. No more guesswork looking at incomplete or incorrect ERP clock-in and clock-out data

Unlock hidden capacity in your machine shop

By planning work with real machine capacity data, you might find you can produce more components in the same time by simply changing work or scheduling practises.

Change your work culture for the better

Having open and reliable production data available to everyone from Machine Setters/Operators to Directors removes gray areas and reduces blame culture.

How can I cost my work better?

Accurate costing is key to competitive success in many subcontract machine shops as well as product manufacturers. Only when you can accurately measure setup and cycle times and machine availability over a Work Order can you really understand what that work order is costing you in labour and machine time. With TrackMyMachines your machinery is monitored 24/7 meaning every single operation is captured and measured.

Learn more about how it worksHow does this work with my ERP system?

ERP systems are fundamental to a well-managed machine shop but don't often contain accurate expected setup and cycle times. With a machine monitoring system like TrackMyMachines, you can start to understand what your true setup and cycle times really are.

Aren't I already measuring this with Shop Floor Data Capture?

When you clock on and clock off a job with Shop Floor Data Capture (SFDC) in your Enterprise Resource Planning (ERP) software, all you get is a time period when some components were probably made. With real machine monitoring, you can see exactly when parts were made and how long they took. Meaning you can track exact machine time back to work orders and start quoting accurately. Once you combine this information with your hourly rates, you get an accurate figure for costs.

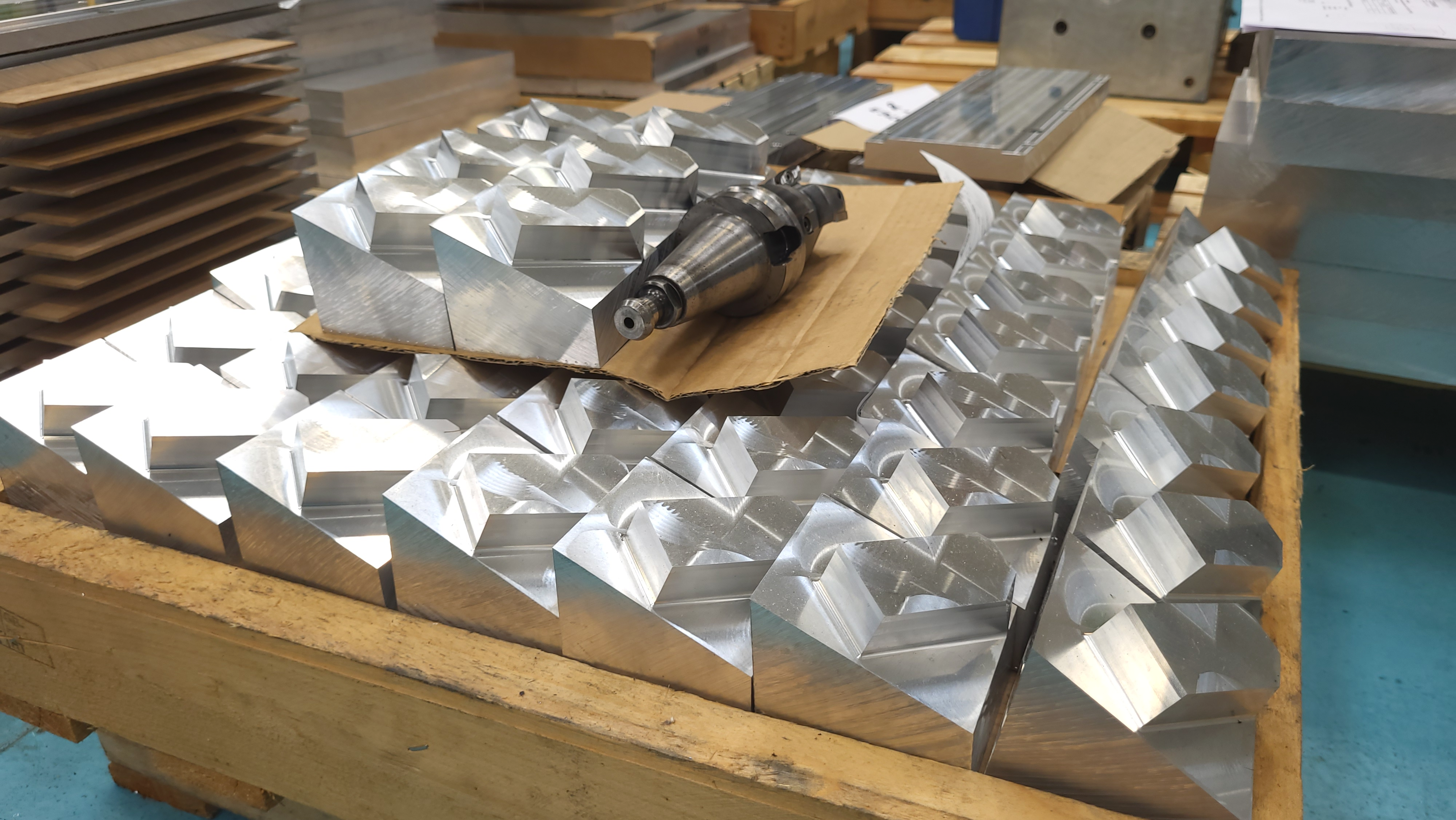

What kind of manufacturers benefit from Machine Monitoring?

It doesn't matter what kind of manufacturer you are, we've got you covered. Since TrackMyMachines is a process visibility tool, our customers use it in different ways. Product manufacturers use our availability charts to see how much capacity headroom they have left, and how many more products they can produce before they need to look for more efficiency or more machinery. Precision subcontract machine shops use our live timelines to monitor production today and be reactive to customer demand. Other manufacturers use our downtime alerts to monitor lights-out production and reduce costly downtime over nights and weekends.

Read more from case studies and technical articles here: