Boost your productivity with CNC Machine Monitoring

Boost your productivity with CNC Machine Monitoring

Trusted by these Manufacturers

Click to find out whyCNC machine monitoring software for your shop floor

TrackMyMachines empowers manufacturers of all types product manufacturers, subcontractors, and bespoke manufacturers with cutting-edge CNC machine monitoring solutions. Our mission is to provide total process visibility into your operations, helping you optimize performance, reduce waste, and maximize margins.

How does monitoring help boost productivity?

In today’s highly competitive manufacturing landscape operational efficiency is the key to success. CNC machine monitoring gives manufacturers the ability to:

- Track Real-Time Performance: See live data on machine utilization, production rates, and more.

- Reduce Downtime: Detect potential issues early and resolve them before they disrupt production.

- Enhance Productivity: Use actionable insights to identify bottlenecks and streamline workflows.

- Improve Quality: Monitor processes and track quality metrics to achieve a more reliable output.

Key Features

Universal Machine Connectivity

Our system integrates seamlessly with any CNC machine—new or old—thanks to flexible IoT connectivity options. From advanced protocols like MTConnect and OPC-UA, and standard current-measurement methods we make it easy to connect and monitor every machine on your shop floor. You can install our hardware in as little as 5 minutes.

Which machines can you connect to?

Our current system supports any machine that draws power when it’s being productive. If you want more than productivity, energy and downtime we can connect directly to:

- Haas with MDC protocol

- Fanuc with FOCAS2 protocol

- Siemens with OPC-UA protocol

- Mazatrol with MTConnect

- Okuma OSP with MTConnect

- Any other machine tool that supports MTConnect

Even bespoke and legacy machines can be connected to TMM. We’re currently monitoring:

- Linishing machines

- Manual milling machines

- Manual lathes

- Plasma and laser cutting machines

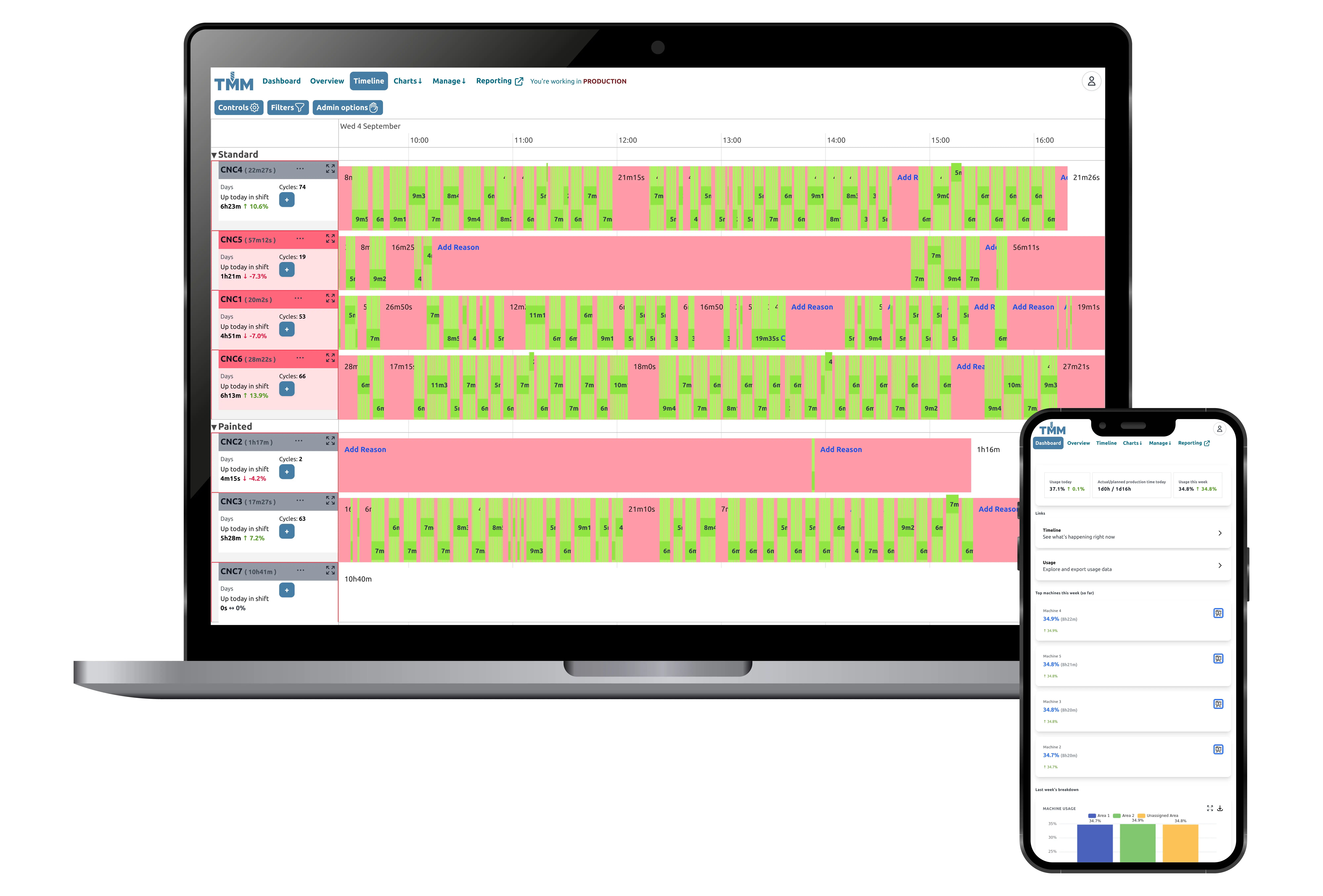

Real-Time Dashboards

Access clear, intuitive dashboards that provide at-a-glance updates on machine performance, OEE, and more. Real-time data ensures you’re always in control, whether on the shop floor or remotely.

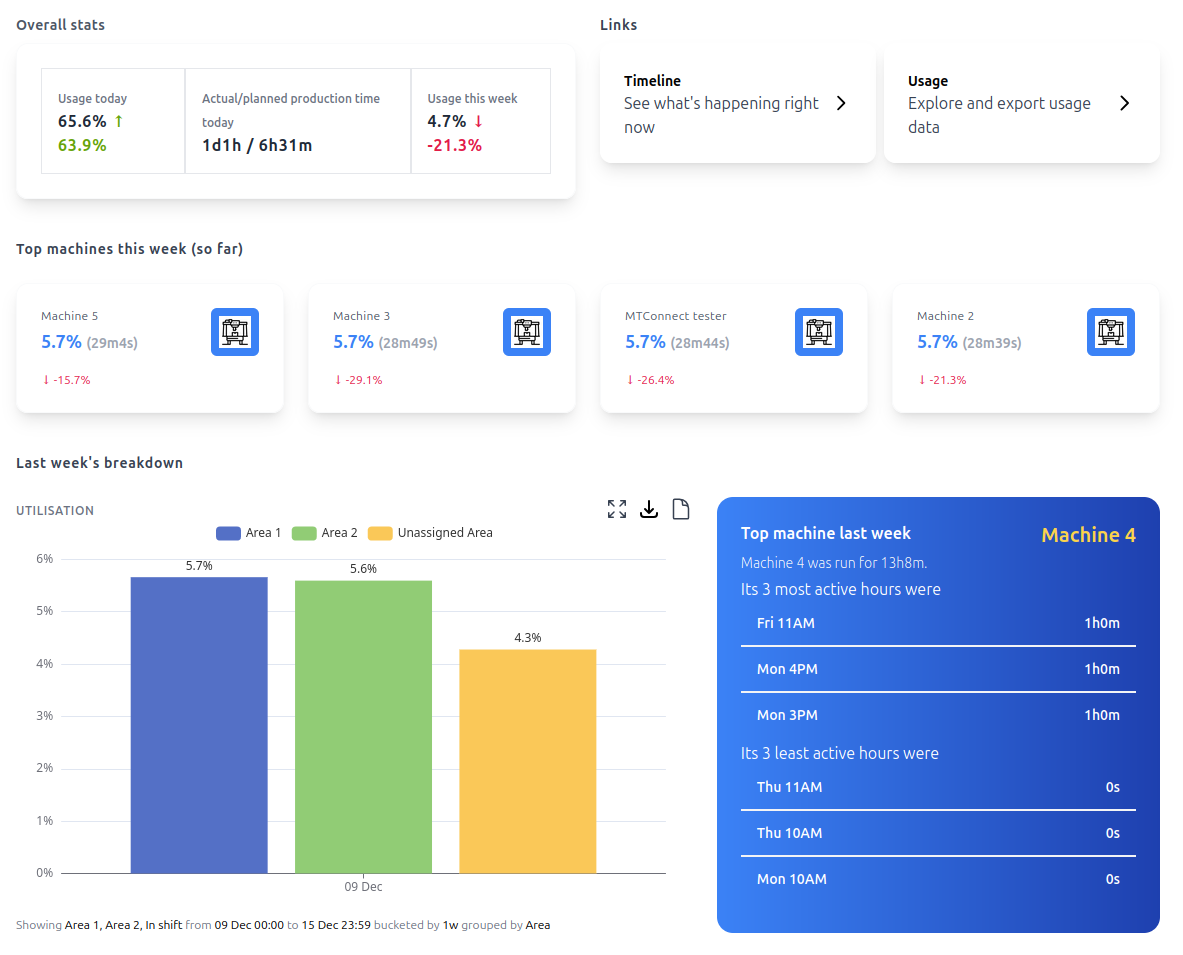

Automated Alerts and Notifications

Get notified the moment an issue arises. Customizable alerts keep your team informed and ready to act, reducing response times and minimizing disruptions.

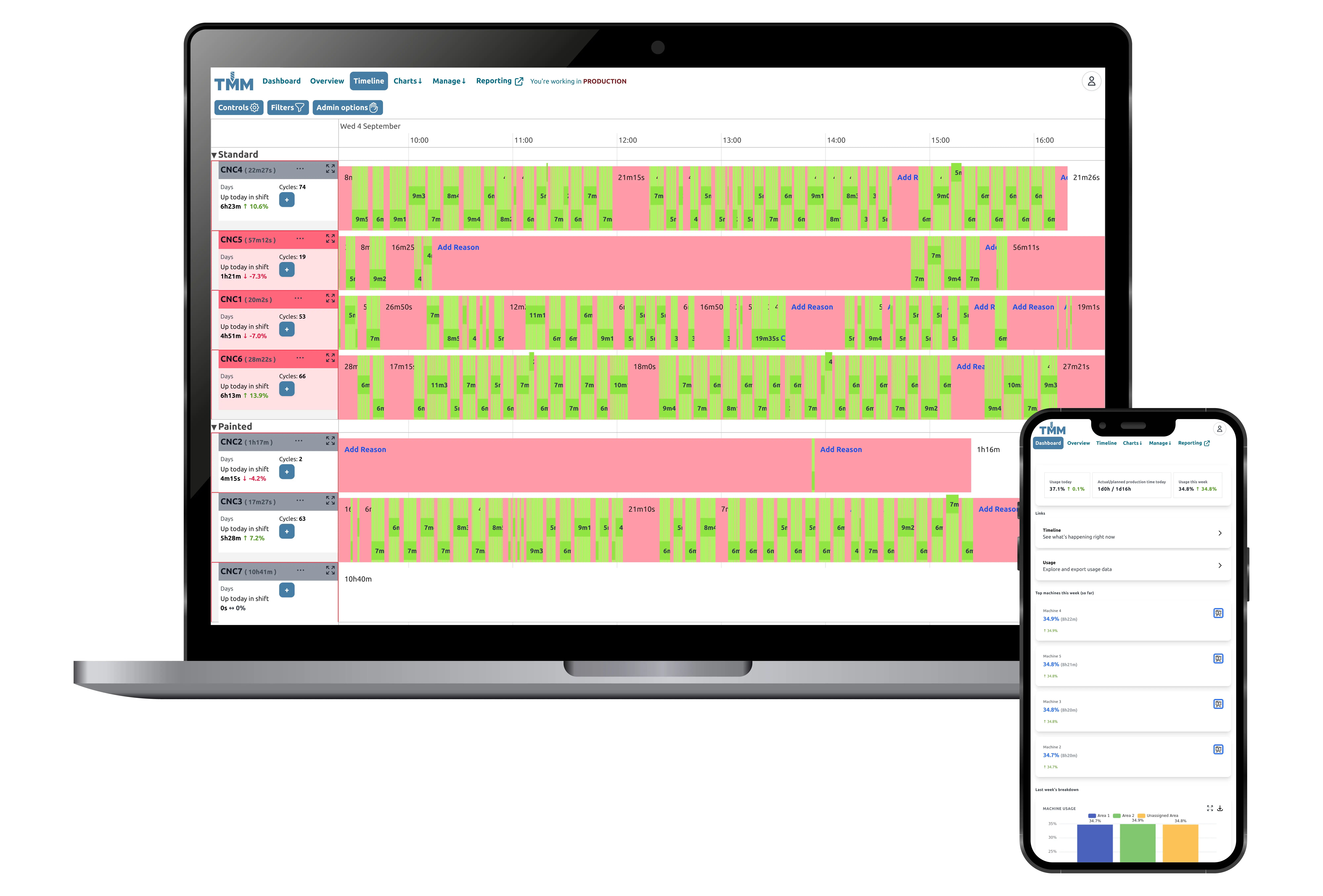

Comprehensive Analytics

Analyze historical performance data to identify trends, assess efficiency, and measure the impact of process improvements. Our detailed reports make it easy to track metrics like downtime, cycle times and overall machine availability.

Operator-Friendly Interfaces

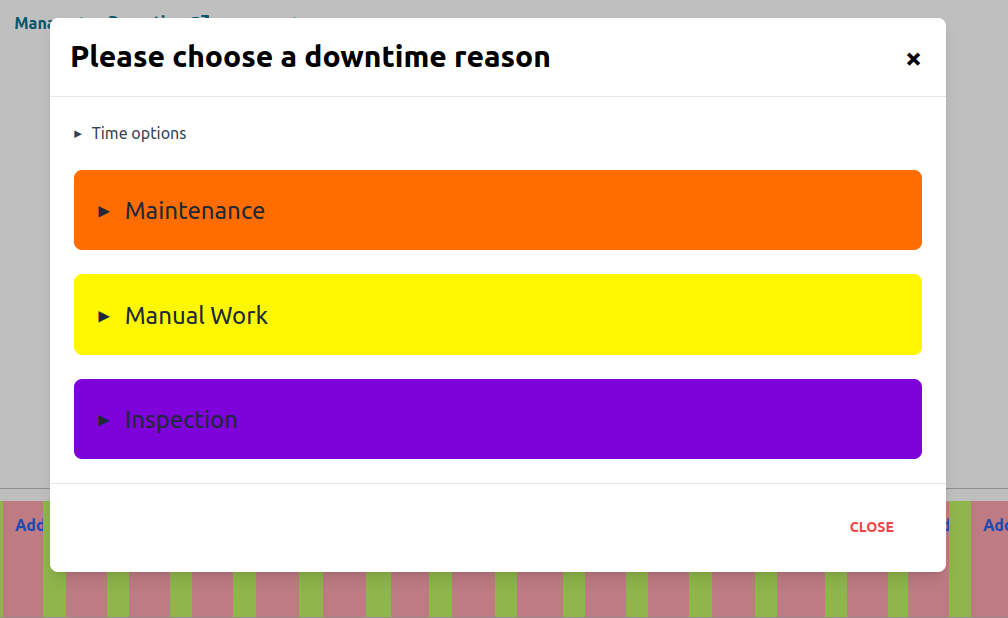

Empower operators with easy-to-use touchscreen tools that allow them to log downtime reasons, track quality, and provide context to machine data—all from the shop floor.

Benefits for Every Manufacturer

Whether you’re mass-producing goods, providing subcontracting services, or crafting bespoke products, our CNC machine monitoring solution delivers tangible benefits:

- Enhanced Operational Visibility: Understand every aspect of your production process.

- Higher Equipment Efficiency: Ensure machines are always operating at their full potential.

- Smarter Decision-Making: Make data-driven decisions to improve workflows and profitability.

Automotive product manufacturer Gardner Denver saved almost £20,000 a month by taking action with machine monitoring

Read the case studyReady to Transform Your Shop Floor?

Join the growing community of manufacturers who are leveraging CNC machine monitoring to stay ahead of the competition. Let TrackMyMachines help you unlock your factory’s full potential.

Contact us today to schedule a demo and see how we can revolutionize your manufacturing operations.