Gardner Denver saves almost £20,000 per year with machine monitoring

Monday Aug 15, 2022

As part of Ingersol Rand Transport Solutions, Gardner Denver manufacture and assemble truck-mounted compressors, blowers and vacuum pumps for the transport industry. Some of their manufacturing is done in-house, and as a constant pressure they must keep up with customer and internal demand.

Most of the compressor components are machined on-site either from cast or billet material on 6 different machining centres. Although they managed to maintain good productivity, they wanted to be able to track exactly how they were doing over time.

After installing TrackMyMachines on their shop floor it was clear where the best gains in productivity could be made.

Add more offsets to the machine tool

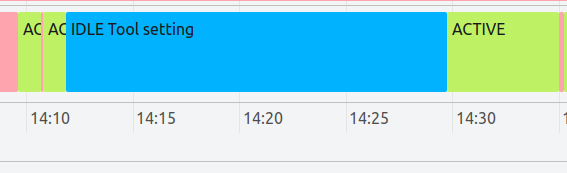

Track my machines showed that a certain VMC with zero point work holding and specialised cutting tools still had considerable downtime from work setting.

Further investigation showed that the machine tool software could be upgraded to hold more tool data. This would reduce the setting time per month, increase productivity and reduce the risk allocated with operator input.

Cost savings: 10 hours/month saves £7200 a year

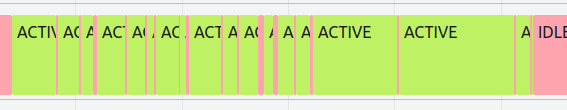

Identification of cycle with too many tool changes

It’s obvious with TrackMyMachines where the tool changes are in your cycle.

After finding the cycle with lots of tool changes, the component was analysed and bespoke cutting tools were designed to reduce the number of tools required. As a result the cycle times were reduced.

Cost savings: £6800 per year

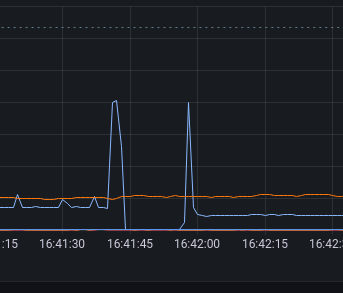

Spot non-conforming castings with spindle power usage

In an FMS system, where multiple types of components are loaded into a pallet system, the inconsistent tool life of a particular tool has been a major concern. In trials the tool life was acceptable, but in production it was unpredictable. It was hard to pinpoint a single cycle that was drawing a larger spindle power than expected when the system is automated and run lights-out.

Carl Parry, Manufacturing Engineer at Gardner Denver explains how he identified the problem: “Track my machines was so simple in showing where the spike in spindle power was, which was then quickly tracked to a particular component and operation. That component was identified as pulling too much power when compared to similar components.

Upon investigation we identified that the initial cutting parameters were incorrect due to non-conforming castings. An additional 5mm of material was present, This was the cause for tool life reduction and tool breakage. Initial tool life was increased after adding additional passes to the machine program.

Because the machine tool has numerous components due to the FMS setup it was very hard to pinpoint the due to the different number of times this particular cutting tool is utilised. Without TrackMyMachines, it would have taken an operator to be present and alert when that particular cycle was being run.”

Tool life increase: 40% Cost saving: £4900 per year

Total cost savings £18,900 per year

If you think you could spot inefficiencies with a machine monitoring system, request a demo now to find out how TrackMyMachines can help improve the way you run your machine shop.