Blog

Here you'll find the articles we've written to help your manufacturing productivity

-

What the 2025 Budget Means for Manufacturers: Getting More from Existing Machinery

Posted by: Rowan Easter-Robinson 2025-12-16

The November 2025 Budget reinforced a clear priority for UK industry: improving productivity. While investment incentives remain in place, many manufacturers are focusing on a more cost-effective approach, maximising the performance of existing machinery before...

Read more...Continuous Improvement: What is Kaizen in Lean Manufacturing?

Posted by: Rowan Easter-Robinson 2025-11-05

At TrackMyMachines, we spend a lot of time helping manufacturers do more with what they already have. Often, the biggest gains come not from big changes but from small, consistent improvements, and that’s exactly what...

Read more...

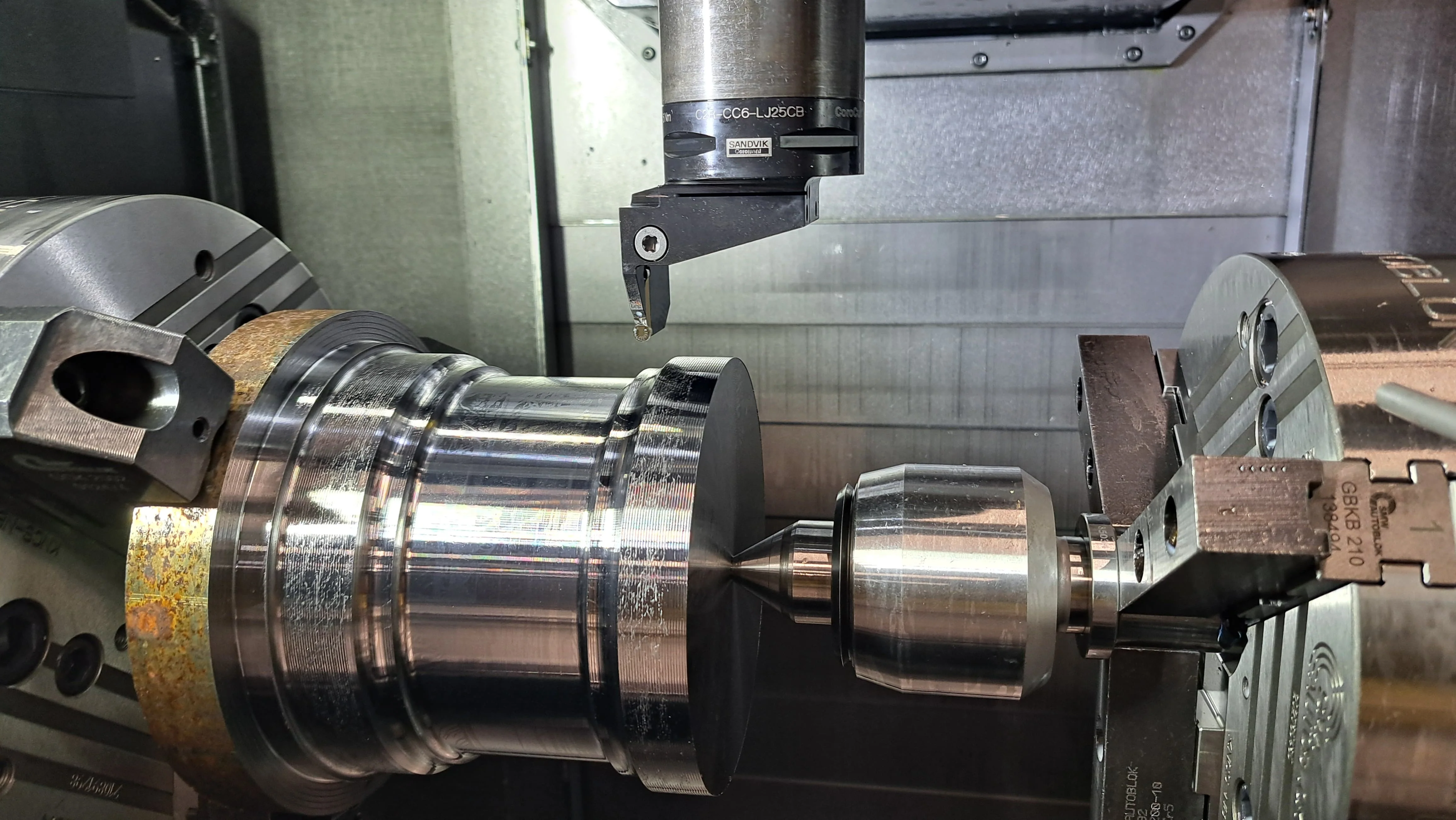

Hidden Capacity: Unlocking CNC Productivity and Profit with OEE Monitoring

Posted by: Rowan Easter-Robinson 2025-09-23

At TrackMyMachines, we see it all the time: CNC hidden capacity OEE reveals untapped potential on shop floors that feels maxed out.Every spindle may seem busy,every operator occupied, yet hidden capacity remains.. The knee-jerk answer...

Read more...

How to improve your Gemba Walk

Posted by: Rowan Easter-Robinson 2025-08-14

At TrackMyMachines, we love the power of Gemba. It means going to the shop floor to see what is really happening. This Lean manufacturing principle has helped countless leaders spot waste, understand processes, and make...

Read more...

How Gardner Denver gained £5,000 of extra machine capacity with TrackMyMachines

Posted by: Rowan Easter-Robinson 2025-07-14

At TrackMyMachines, we love seeing our platform drive real operational change. That’s why we’re proud to share how our long-time customer, Gardner Denver, used a single insight from TrackMyMachines to make a small adjustment —...

Read more...

How to Apply Continuous Improvement in CNC Manufacturing

Posted by: Rowan Easter-Robinson 2025-06-08

Everyone talks about continuous improvement. But in most CNC shops, it’s not always clear where to start. The reality is: continuous improvement doesn’t have to mean huge overhauls. Often, it’s about fixing the basics—then building...

Read more...

What we learned at Smart Factory Expo 2025

Posted by: Rowan Easter-Robinson 2025-06-06

This year’s Smart Factory Expo made one thing very clear: for many manufacturers, planned production data is broken. We spoke to CNC shops struggling with the same core issue—badly estimated setup and cycle times. Most...

Read more...

TrackMyMachines at Smart Factory Expo 2025: Unlock the Potential of Your Manufacturing Operations

Posted by: Rowan Easter-Robinson 2025-04-25

At Track My Machines, we’re excited to share that we’ll be exhibiting at the Smart Factory Expo during Smart Manufacturing Week, from 4th to 6th June 2025 at the NEC in Birmingham. As leaders in...

Read more...

The Hidden Cost of Long Lead Times on Your Shop Floor

Posted by: Rowan Easter-Robinson 2025-04-07

If your machines only make parts when someone’s watching them, you’re leaving money on the table. Long lead times aren’t just an inconvenience—they’re a red flag. They point to underutilised equipment, inefficient processes, and missed...

Read more...

5 Signs CNC Machine Monitoring Is Right for Your Business

Posted by: Rowan Easter-Robinson 2025-03-21

Many manufacturers struggle to determine whether machine monitoring is worth the investment. If you’re unsure whether tracking your machines in real-time will benefit your shop, there are a few key indicators to consider. This article...

Read more...

The trouble with Shop Floor Data Capture (SFDC)

Posted by: Rowan Easter-Robinson 2025-01-17

As a data-driven manufacturer, you’re always looking for ways to optimize efficiency and make informed decisions. One of the most common approaches we see in industry is Shop Floor Data Capture (SFDC)—a method for logging...

Read more...

How DoorCo Improved Production by 26% with TrackMyMachines

Posted by: Rowan Easter-Robinson 2024-12-09

We interview Chris Mansfield, Senior Manufacturing Manager at DoorCo Ltd, who explains how TrackMyMachines has shifted the production culture at their Macclesfield Site. About DoorCo DoorCo is a global leader in composite door manufacturing, celebrated...

Read more...

CNC Machining Sustainability

Posted by: Rowan Easter-Robinson 2024-11-18

Achieving a sustainable manufacturing process is a requirement for companies around the world to continue operating. As well as new EU Regulations coming into force 2025 and beyond mean that carbon accounting is becoming more...

Read more...

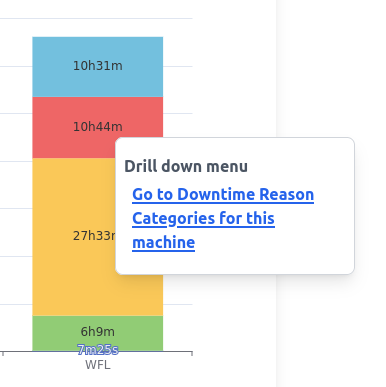

Five production mistakes you could fix today to reduce your machine downtime

Posted by: Rowan Easter-Robinson 2024-10-11

Looking at the data from our Q2 Downtime Reason Report, we’ve come up with 5 top tips to reduce your downtime. 1. Letting machines run without proper servicing According to our report, reducing machine breakdown...

Read more...

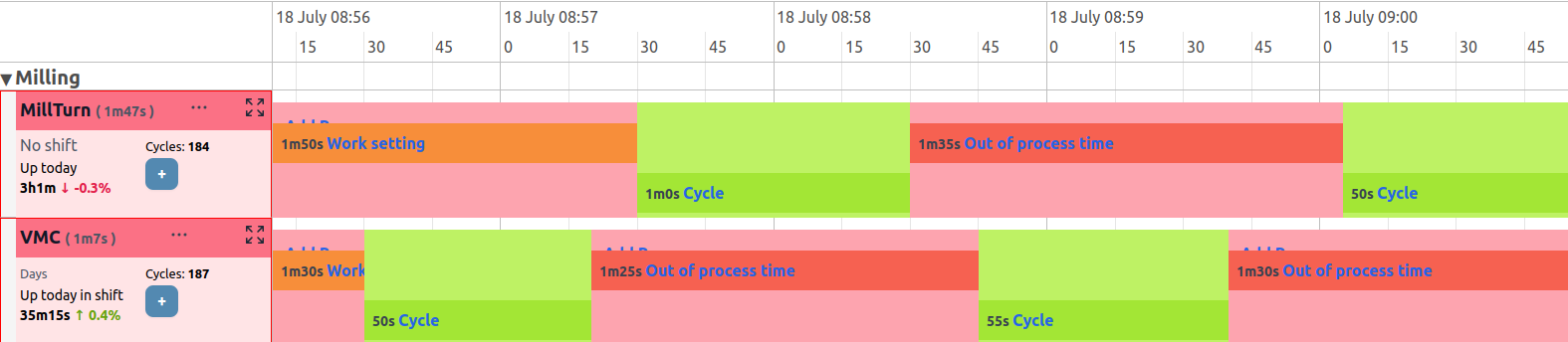

Improving your productivity with Machine Monitoring

Posted by: Rowan Easter-Robinson 2024-10-10

We’ve helped manufacturers just like you improve their productivity by 26% and reduce their costs by £20,000 per year. Our focus is on simple and easy process visibility. If it’s your first time monitoring your...

Read more...

Data Driven Manufacturing (And how to do it)

Posted by: Rowan Easter-Robinson 2024-09-20

Learn how to implement data driven manufacturing in your factory today. Manufacturers are starting to realise the need to use their manufacturing data to take action. Sometimes actually making that data available is the first...

Read more...

How to monitor the energy use in your factory

Posted by: Rowan Easter-Robinson 2024-08-12

With electricity costs increasing it’s hugely important to measure your energy usage so you can try to reduce it. One way companies do this is by using their probably already installed distribution board. Modern boards...

Read more...

Downtime reason report Q3 2024

Posted by: Rowan Easter-Robinson 2024-07-29

We’re already more than halfway through 2024, and our customers have been logging their downtime reasons to help spot the highest contributing factors to their machine downtime. I’ve crunched the data for the first half...

Read more...

Can you increase machine capacity without buying a new machine?

Posted by: Rowan Easter-Robinson 2024-07-18

Trying to keep up with manufacturing demand is hard when you feel like you’ve not got enough machine capacity available. The obvious solution is to buy a new machine, but with economic and political uncertainty...

Read more...

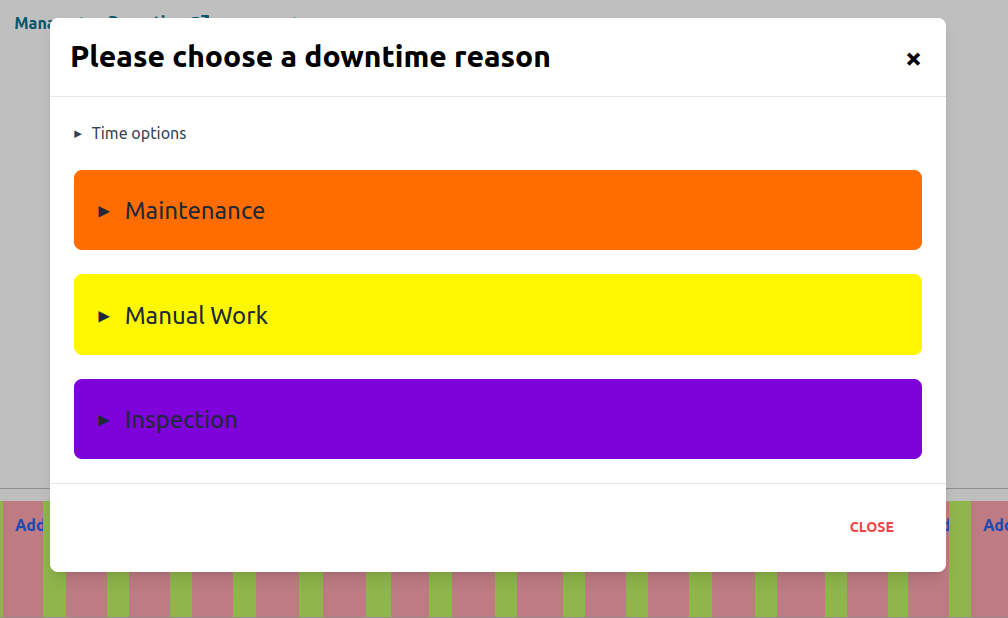

What's better than a Kaizen Event?

Posted by: Rowan Easter-Robinson 2024-07-10

When a machine isn’t as efficient as it could be, it’s important to find out its main reasons for downtime. Doing a downtime analysis in the traditional way, a Kaizen Event, can be useful but...

Read more...How does lean manufacturing apply to machine shops?

Posted by: Rowan Easter-Robinson 2023-04-05

If you’ve been around engineering for a while you’ll have heard the term Lean Manufacturing, sometimes just referred to as Lean. I’ve heard it used a lot when engineers and managers are trying to improve...

Read more...

Gardner Denver saves almost £20,000 per year with machine monitoring

Posted by: Rowan Easter-Robinson 2022-08-15

As part of Ingersol Rand Transport Solutions, Gardner Denver manufacture and assemble truck-mounted compressors, blowers and vacuum pumps for the transport industry. Some of their manufacturing is done in-house, and as a constant pressure they...

Read more...

Why OEE might not be the right metric for CNC productivity

Posted by: Rowan Easter-Robinson 2022-07-30

OEE (Definition) is a measure touted by a lot of manufacturing management experts. It supposedly combines three metrics into one single measure that represents your shop’s productivity. Like many simplifications however, this doesn’t fully capture...

Read more...What is planned and unplanned downtime in Manufacturing?

Posted by: Rowan Easter-Robinson 2022-03-14

Running machines doesn’t always go smoothly. Any experienced CNC operator can tell you about all the different ways a machine can be disabled. From bad coolant to a broken spindle there’s tons of ways downtime...

Read more...Manufacturing downtime tracking software

Posted by: Rowan Easter-Robinson 2022-01-31

So you need some downtime tracking software? There’s plenty of options available on the market. Between many incumbents like Amper and MachineMetrics, it’s hard to choose which machine monitoring system to go for. It’s probably...

Read more...Machine Monitoring software could be free

Posted by: Rowan Easter-Robinson 2022-01-28

If you’re interested in machine monitoring, you probably want to try it out before you buy. It’s a difficult product to do a cost-benefit analysis on. Once you estimate the ROI from machine monitoring then...

Read more...Free Machine Downtime Tracker Excel Template

Posted by: Rowan Easter-Robinson 2022-01-20

If you’re trying to monitor your machine shop, you’ll probably want to measure downtime. It’s hard enough trying to get your operators to buy in, and most of the time they’ve got more important things...

Read more...How to collect data from your CNC machine

Posted by: Rowan Easter-Robinson 2022-01-13

If you need to see what’s costing your business money, you need to know how much your machines are down. There are some manual methods you could use, the simplest being an excel spreadsheet. You...

Read more...3 Ways to improve your machine productivity

Posted by: Rowan Easter-Robinson 2022-01-10

Whether you’re a subcontract machine shop or a product manufacturer, machine productivity is a critical measure of your performance as a business. Depending on your environment, different manufacturers need to optimise for different things. Increasing...

Read more...What is machine monitoring?

Posted by: Rowan Easter-Robinson 2022-01-05

When you run a machine shop knowing exactly how long it took you to make a part is critical for making sure you’re profitable and competitive. When you’re busy keeping the business going it’s impossible...

Read more...