Achieving a sustainable manufacturing process is a requirement for companies around the world to continue operating. As well as new EU Regulations coming into force 2025 and beyond mean that carbon accounting is becoming more of an integral part of a businesses day to day book-keeping and accounting.

Carbon accounting

The European legislation, the Corporate Sustainability Reporting Directive (CSRD) will require companies to publish their first report in 2025. Some UK companies must follow this legislation even though they’re not technically based inside the EU. The reporting must cover Scopes 1 to 3 of the Greenhouse Gas Protocol.

Even if as a company you don’t have to report these figures, if you supply components to companies inside the EU, they may ask you for your Scope 1 and 2 emissions to fulfil their requirements. If you can provide these details accurately and simply you could be preferred as a supplier over companies that can’t provide this information.

The need to start to measure and manage this aspect of business operations means that capturing energy usage data from machines is essential. Once the energy consumption of machinery is measured, direct carbon emissions can be attributed per component manufactured.

Not only does this allow for companies to account for the carbon impact of their products, but changes can be made to reduce that impact.

Energy costs still matter too

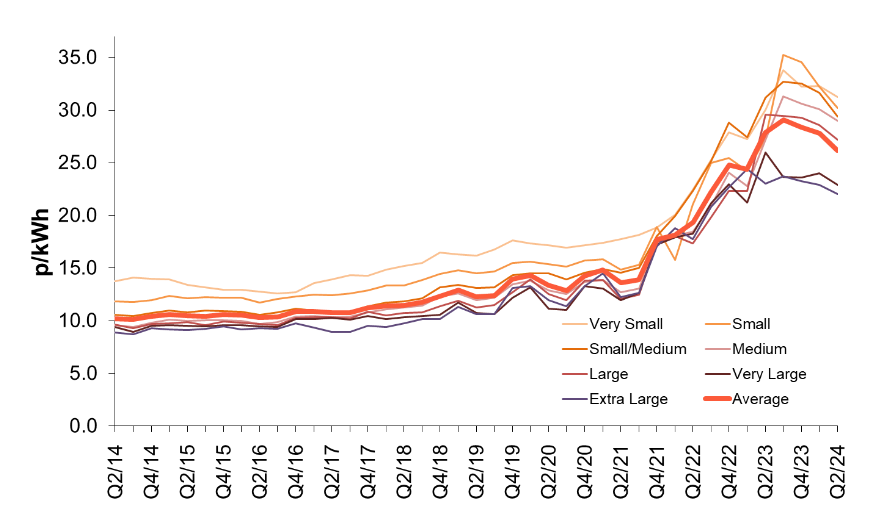

Non-domestive energy costs are still much higher than they were a few years ago, and this means that the cost of producing a component is also higher. Getting a handle on the energy used to produce a component now will set manufacturers on a firmer footing for when energy costs inevitably increase further in the future.

Much like carbon accounting, it’s not necessary immediately for your bottom line, but it will be needed very soon.

TrackMyMachines comes with Energy Estimation for both carbon accounting and energy costs

With TrackMyMachines not only can you visualise your production process, you can now estimate the energy consumption of your machinery. This means carbon accounting your production process becomes so much easier.

The good news is that energy costs can also be measured with TMM, meaning you get a more granular cost of production too. Incorporating this into your costing models means you can include not only machine time for a component but real energy costs right now.