Whether you’re a subcontract machine shop or a product manufacturer, machine productivity is a critical measure of your performance as a business. Depending on your environment, different manufacturers need to optimise for different things.

Increasing productivity for a machining subcontractor

Subcontractors probably make extremely different parts weekly, or even daily. When a different job comes through the door each day sometimes you’re working flat out just to get good parts made. It probably feels like you’re running to stand still. As a machining subcontractor your job is to get good parts turned around fast. When this is your priority, often a lot of potential productivity gains get lost in the confusion.

1. Keep your job information organised

Each job you do has at least some of these items:

- Soft jaws

- Custom fixturing

- Part drawings

- Part programs

- CAD Models

- CAM Files

- Assorted nuts, screws for fixture assembly

- Material quotations and material data

- Part quotations

Regardless of the fact some of these are physical/nonphysical. If you do a good job making that part you’ll probably get a repeat order. When you do, if you’ve rushed the first production job, there’s information here you’ve lost that is critical to the job. If you’ve got it on-hand then you’ll save a huge amount of time and money.

How to save this information

Simple, start with an excel spreadsheet that logs the customer request, the date and a job ID. Create a folder for each job ID that everyone can access. Just dump everything you have in that job ID folder.

For the physical items (soft jaws, custom fixturing etc) get some racking, label each racking box with the job ID and put your job-specific items in it.

This kind of organisation also helps move your business towards ISO9001 accreditation.

2. Improve your production planning with machine monitoring

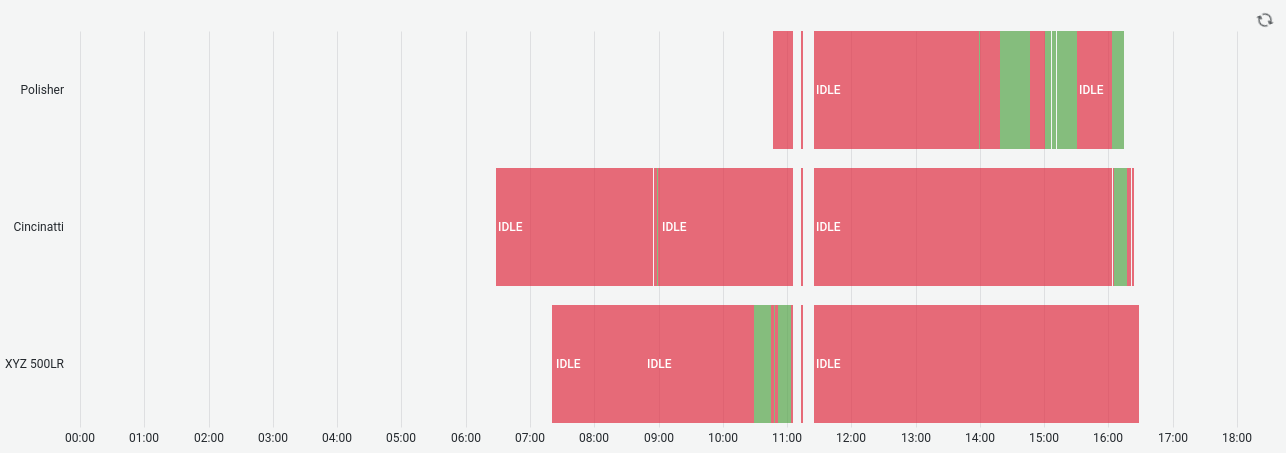

If you’re interested in maximising your machine productivity, you need to know what’s happening on your shop floor. With machine monitoring you get a full view of your machine shop.

Sometimes machines don’t run for half the time you expect them to

If you don’t know what’s happening on your shop floor, there is no way to know which machines are productive. Before you start to optimise production, you need to find out which machines are performing as you expect. Sometimes machines don’t run for half the time you expect them to, once you know which machines aren’t performing - then you can start improving.

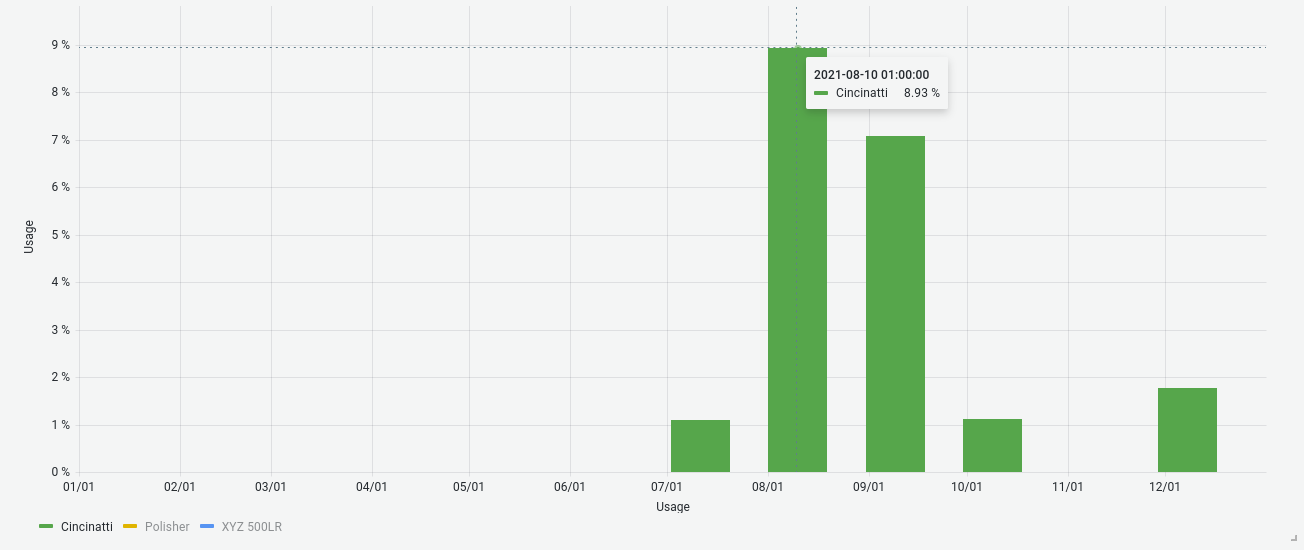

As well as seeing what’s happening on your shop floor right now - historical information on how your machines are performing is also really useful. The average usage for a machine in a small shop can be as low as 9%.

The average usage for a machine in a small shop can be as low as 9%.

3. Reduce setup times by improving your workholding

Smaller batches, look for quicker changeover times

If you’re changing jobs a lot you need to improve your changeover times. Rather than putting your workholding straight on the machine bed T-slots, put it on a sub plate.

Build a sub-plate

A sub-place is a flat piece of steel or aluminium with fastening (screw) and positioning (dowel) holes. The positioning holes, if they’re accurate, should be repeatable to around 5 micron. Imagine reconfiguring a machine to a completeley different job in minutes with 5 micron repeatability. That’s a ridiculous saving over a few months!

Get a modern vice

Once you’ve got your sub-workholding fast to change and repeateable, think bigger than a stiff old machine vice! There’s loads of off-the-shelf work-holding that’s perfect for subcontractors one-off and batch work.

When looking for a new vice, look for:

-

How many allen bolts you have to undo to change jaws, the fewer the better!

-

If you can, look at the pitch of the leadscrew. If it’s steeper it’ll be quicker to open the vice or close it. Some vices (like the Chick One-Lok) have a ratchet mechanism to even make opening and closing the vice for different sized jobs quicker.

Just because you’re not doing a huge amount of repeat work that doesn’t mean you can’t reduce your setup times. But if you do get repeat work, milling your own soft jaws for quick-change vices could save you hours in the long run.

Bigger batches, present more components to the spindle at once

If you’ve got larger jobs, you have to get better than just a vice, no matter how fast your process is. If someone can put 10 parts in the machine at once when you’re only putting 1 in, they’re making them cheaper than you, no matter how quick you’re doing it.

There’s loads of ways to present more parts to the spindle. One method is custom fixturing, rather than putting one or two parts in a machine vice, design a new base that fits on your sub-plate and uses Mitee Bites to clamp the parts with a low-profile.