When you run a machine shop knowing exactly how long it took you to make a part is critical for making sure you’re profitable and competitive. When you’re busy keeping the business going it’s impossible to be everywhere at once and this information gets lost in the fog of manufacturing.

Without machine monitoring production you’ll get second-hand information from operators and have to piece together exactly what machines were doing. You’re only getting half the picture at the best of times. This makes it really difficult to accurately cost parts and make money.

Machine monitoring is key to understanding exactly what’s happening on your shop floor. With machine monitoring you get a transparent view of your machine shop at all times. This makes it easier to visualise both the path a part takes through your shop, and what a machine’s workload looks like for a given day.

How it works

TrackMyMachines offers a small sensor box for each machine, that’s powered by 24v from inside the machine cabinet. A current sensor plugged into the sensor box measures the power drawn by the machine. The power drawn by the machine indicates whether it’s in cycle or not.

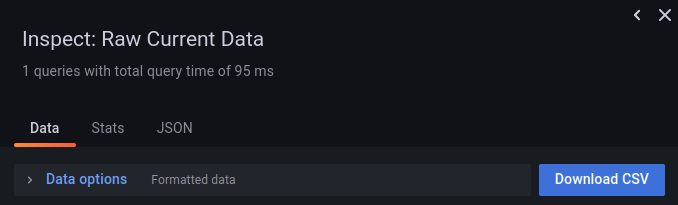

We collect this machine power data and convert that into on/off periods with some analytics, and show the results on a webpage you can access from anywhere. You own your data and can export it to a CSV (spreadsheet) file any time you want.